How does variable valve timing work ?

Automobile manufactures ues several ways to accomplish VVT. 1. Exhaust only. 2. Intake only. 3. Dual equal. 4. Dual Independant.

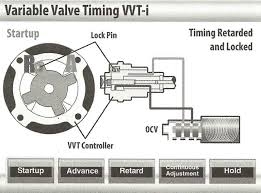

The PCM calculates and determines the desired camshaft position. It will continually update the VCT solenoid duty cycle until desired positioning is achieved. When the VCT solenoid is energized, engine oil is allowed to flow to the VCT actuator assembly which advances or retards the cam timing. One half of the VCT actuator is coulped to the camshaft and the other half is connected to the timing chain. Oil chambers between the two halves couple the camshaft to the timing chain. When the flow of oil is shifted from one side of the chamber to the other, the differential change in oil pressure forces the camshaft to rotate in either an advance or retard position depending on the oil flow.

Service Issues

For the VVT system to operate properly, the engine oil must be clean and at the proper level. The correct viscosity and type of oil must be used and the oil filter must have a drain back valve if the vehicle was equipped with one originally. Adequate oil pressure is required to operate the VVT system.